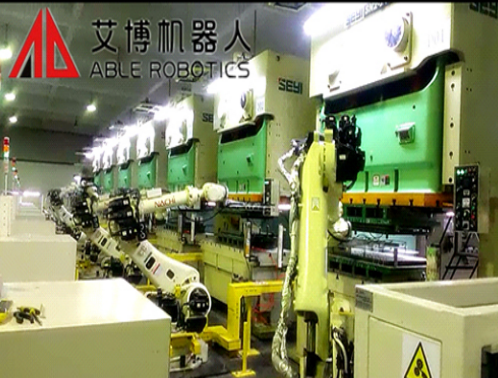

Adopting FANUC robot with visual inspection to realize automatic loading and unloading of automobile insulation board

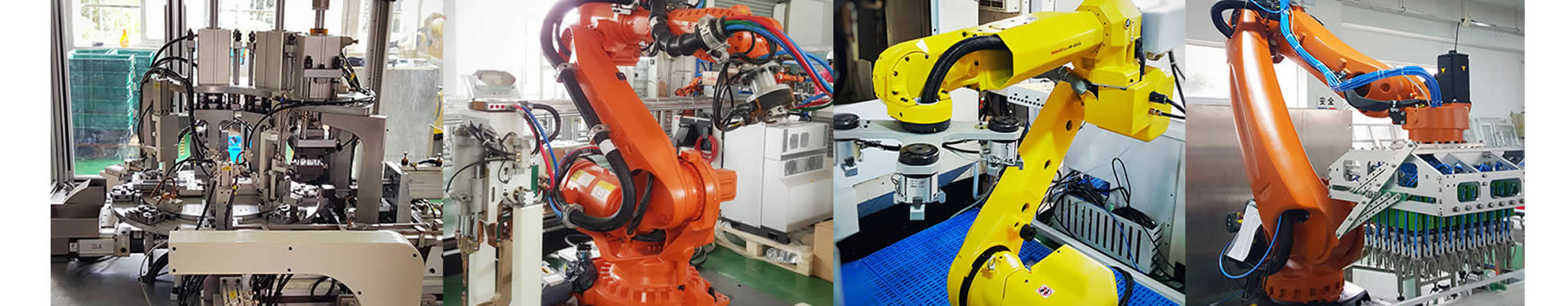

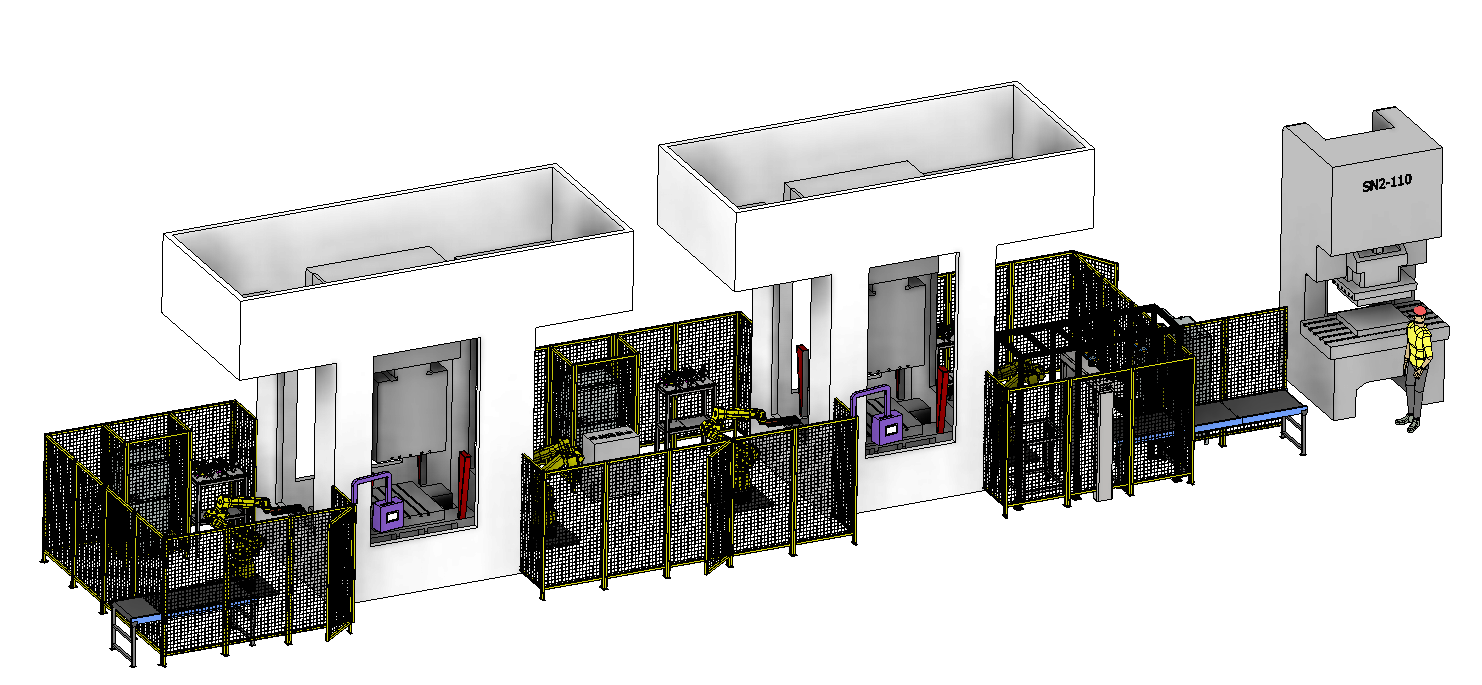

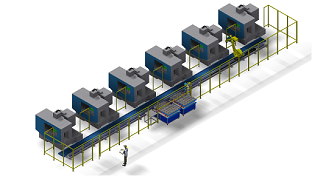

1 The forming blanking robot takes the fixture of the corresponding product from the transfer fixture bracket and places it on the transfer table and exchanges the corresponding claws from the cross-replacement bracket;

2 The forming blanking robot removes the molded product from the molding machine:

A: If the product needs to be turned over, directly transfer the product to the punching robot.

B: If the product does not need to be turned over, place the molded product on the transfer table;

3 The punching loading robot (take the product from the transfer station) feeds the punching press.

4 Finished material cutting robots change from quick change

5 The finished product unloading robot removes the finished product from the punching press and places it on the unloading streamline and manually collects it.

Auto parts, food, daily necessities industry